Manufacturing ballistic protection shelters for the military

Multiple Awards | $1,452,925

15,000

ESPS modules contracted to the US Army

20,000

Square foot precision manufacturing facility

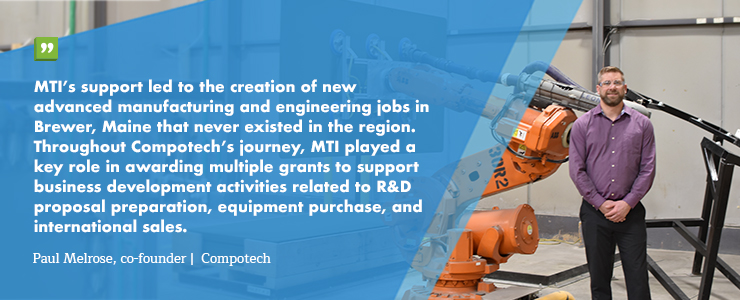

As a spin-off from the University of Maine’s Advanced Structures and Composites Laboratory, Compotech has evolved from a two-person engineering company into one of Maine’s top composite and precision manufacturing companies creating next-generation, blast and ballistic protection systems and structures. MTI has been a partner in its growth since its inception in 2012.

Its flagship product — the Expeditionary Shelter Protection System — has advanced from R&D to production through key contracts with the US Army and with financial and non-financial assistance from MTI.

The ESPS uses advanced armor technology that protects against ballistic projectiles and blasts. These walls — made of fiber-reinforced polymer composite — are lightweight, mobile, and easy to deploy making them ideal for safeguarding everything from tents and containers to hospitals and government buildings. They can be strategically placed for optimum safety and protection.

The development of this innovative shelter protection system began by using MTI’s Technical Assistance Program (TAP) team to help write a successful proposal for the Department of Defense to fund their design and prototyping research. The multi-million dollar research contract led Compotech to develop FRAG-CT software for the Army. Two hundred times faster than hand-count methods, the platform streamlines the collection and analysis of explosion data and was called one of ‘the most transformative security innovations of 2021’ by Popular Science. This bomb shrapnel data helped Compotech, and the Army refine the design of the Expeditionary Shelter Protection System.

After finalizing the design and passing rigorous tests, Compotech was awarded a very competitive multi-million-dollar contract with the US Army to produce thousands of units of ESPS.

This required Compotech to quickly build out its in-house manufacturing capabilities and hire skilled technicians in order to meet its production goals. A loan from MTI enabled Compotech to have the necessary capital to build a state-of-the-art production line at its facility in Brewer, Maine. Compotech’s workforce doubled in 2021 when the manufacturing line started.

In addition to financial resources, MTI has provided Compotech with E-Residents, who brought mentorship and advice that helped Compotech grow and strive to be one of the top ten defense companies in Maine.

The successful launch and growth of Compotech allows co-founder Paul Melrose to work in-state alongside other native Mainers, who might otherwise have had to leave the state to find similar employment. With a mission of serving the defense industry with ‘Made-in-Maine’ solutions, Compotech will continue to bring new engineering and precision manufacturing jobs to Maine.